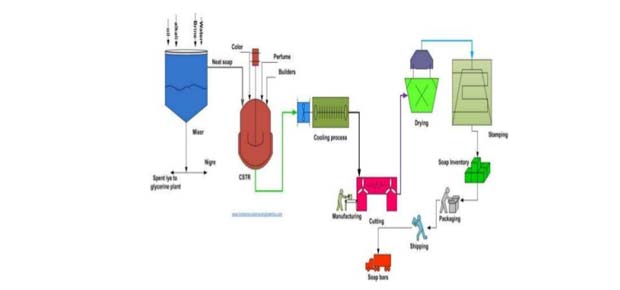

The manufacturing of soaps and detergents is a complex process that involves different activities and processes. The size and complexity of these processes and activities may range from small manufacturing plants that employ a small number of people to those with hundreds and thousands of workers. products may range from all purpose products to that are used for a specific application or requirement.

The first phase in the manufacturing of soaps and detergents is the selection of raw materials. Raw materials are selected on the basis of various factors, including - cost, human and environmental safety, compatibility with other ingredients, and the performance characteristics and appearance of the final product. While the actual production process may vary from company to company and manufacturer to manufacturer, there are some steps, which are common to all types of cleaning products.

Saponification processes are chemical soap manufacturing processes that produce soap from fatty acid derivatives. Saponification process for soap manufacturing involves hydrolysis of esters under basic conditions to form an alcohol and the salt of a carboxylic acid (carboxylates). Saponifiable substances are the soaps and detergent ingredients that can be converted into soap.

In Saponification soap manufacturing processe, vegetable oils and animal fats are used for making soaps. Triesters or Triglycerides are the greasy materials derived from these diverse fatty acids. Soap manufacturing is doen in a one-step or a two-step process. In the one-step soap manufacturing process, the triglyceride is treated with a strong base, for example, lye, that accelerates cleavage of the ester bond and releases the fatty acid salt and glycerol. This one step soap manufacturing process is the key industrial method for producing glycerol. Sometimes soaps may be precipitated by salting it out with saturated sodium chloride. For soap manufacturing, triglycerides are highly purified but saponification process includes other base hydrolysis of unpurified triglycerides. For example the conversion of the fat of a corpse into adipocere, sometimes known as "grave wax." This soap manufacturing process is more common where the amount of fatty tissue is high, the agents of decomposition are absent or are negligibly present, and the burial ground is particularly alkaline.

Manufacturing of soaps and detergents can be broadly categorized into Five main types -

If you have decided to make soap at home, you will need soap making supplies in the form of raw materials, soap making equipment & tools ...

Read More

Someone has rightly said that clothes are not just clothes. They form an integral part of a person's personality and tell a lot about their nature and...

Read MoreCleansing products play an important role in the daily lives of people.

Both soaps and detergents are cleansing products that we frequently use in our

Soap is designed as a product to be used once and then flushed down the drain...